Caring for your Jewellery while abroad

Heading to the Mediterranean this season? While you soak up the sun, make sure your diamonds are just as radiant when...

In 500 years up to 2004 there were around 163 plus 200ct large diamonds found. About one a year for the past century. Since then 3 huge diamonds over 200ct have been found each year!

Since 2004, 47 huge diamonds have been found at an average of +400ct each or 19,000cts in total.

“Lesedi la Rona,” -The second-largest diamond ever found. The 1,109-carat white diamond was unearthed in November 2015 in Botswana.

“Graff Lesedi La Rona”, a 302.37 carat D-color diamond polished from a 1,109 ct rough diamond

Planning and cutting take many months to complete.

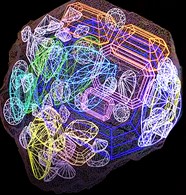

The diamond cutting (pictured above) was planned using software that Garry Holloway patented with Sergey Sivolenko.

This one diamond is worth $53 million – more than $49 million Lucara paid De Beers for the Mine in Botswana in 2009. They knew that X-Rays would make them rich.

… most large diamonds were alluvial found in river beds. All of the +200ct diamonds found since 2004 were from hard rock mines.

Modern miners XRay ore before crushing it. Diamonds are invisible to XRays and if there is a void inside the rock they carefully open the rock and find a big rough diamond!

There are 3 times as many huge diamonds found each year.

In 500 years prior to 2004, there were around 163 plus 200ct diamonds found. Since 1890 when large-scale African diamond mining got underway there have been about one huge diamond found a year.

In the 16 years since that have been at least 47 found weighing an average of +400ct each or 19,000cts in total. Today there are 3 found a year.

Many of the earlier large diamonds were alluvial or found in river beds. Most of those river deposits have since been identified and mined out. It is possible that there have been other large diamonds discovered that have not been publicly disclosed. Artisanal miners do not always declare their large finds for fear of being robbed.

All of the reported +200ct diamonds found since 2004 were from hard rock mines.

See the list of the largest found rough diamonds here.

Man-made or Lab-grown diamond companies claim that their technology is more environmentally friendly than mining natural diamonds. However, miners are using new advanced technologies that are kept as trade secrets. Most of us have become rather used to reading that another 100ct, 500ct, or +1,000ct rough diamond has been unearthed. What you may not have noticed is this has only been happening for a decade or so.

In the past 12 years or so the use of XRT (X-ray transmission sorting technology) has meant the discovery of about 100 times more +100ct rough diamonds from mines. And has reduced the water and energy usage by a huge amount. Diamonds (and coal) can be detected in ore rocks up to 15cm or 6 inches as they pass along conveyor belts to and from crushers. This is because carbon is a very ‘atomically light’ material and X-rays pass straight through making separation from other rocks easy with X-ray technology – rather like identifying bones from soft tissue.

Production runs of about 1,000 tons per hour of diamond-bearing kimberlite are being achieved. This and other sensor-based separation technologies have replaced dense media separation (DMS) which is highly energy-intensive. These are either water-based huge washing machines of more commonly high-pressure air cyclones where diamonds being about 3.5 times heavier than water drop out the bottom and lighter 2-2.5times heavier than water rocks get blown away. These processes use more water and/or energy and result in the need for several successive crushing and DMS separations.

Near infra-red (NIR) sensors are used in some diamond mines to identify diamond-bearing kimberlite from surrounding non-diamond yielding material like granites etc.

These fields of science are secretive and still rapidly developing and will only improve the yields from existing mines. This also explains why some ex De Beers mines that the company closed and sold off to junior miners are now producing many high value and profitable diamonds. The next stage of development is likely to be the use of underground XRT and NIR plants employed in underground mines reducing the need to cart ore to the surface using a lot of energy and then creating huge piles of waste rock. What is more, it is likely that Rio Tinto will find a junior miner buyer for Argyle and if so, that new company may install XRT and NIR down the deep mine at Argyle.

De Beers is also exploring carbon capture in kimberlite so leaving the kimberlite down a deep mine could make diamond mining carbon positive!

Heading to the Mediterranean this season? While you soak up the sun, make sure your diamonds are just as radiant when...

When it comes to purchasing an engagement ring, the diamond isn’t the only star of the show. The setting style can...

Investing in gold jewellery is a time-honoured tradition that continues to shine in 2025. Gold has been a reliable...